Contents

- 1 Introduction to the Simmons 4 Inch Well Seal Maintenance Port Diagram

- 2 Components of the Well Seal and their Functions

- 3 Importance of Proper Maintenance

- 4 Step-by-Step Guide for Cleaning and Inspecting the Well Seal

- 5 Troubleshooting Common Issues with the Simmons 4 Inch Well Seal

- 6 When to Replace Your Well Seal

- 7 Tips for Choosing a Quality Replacement Well Seal

- 8 Conclusion

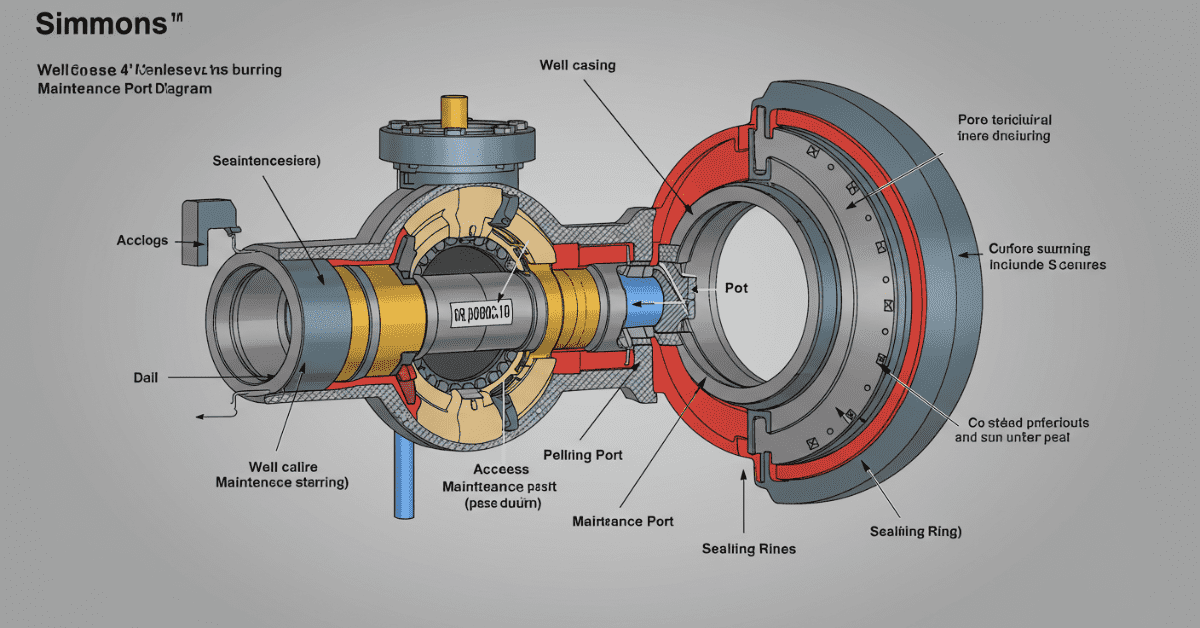

Introduction to the Simmons 4 Inch Well Seal Maintenance Port Diagram

When it comes to maintaining a reliable water supply, the Simmons 4 Inch Well Seal stands out as an essential component. This robust device not only protects your well but also plays a crucial role in ensuring clean and safe water access for you and your family. However, like any other mechanical part, proper care is necessary to keep it functioning optimally.

Have you ever wondered about the inner workings of this vital seal? Or perhaps you’re facing some issues that need addressing? Don’t worry! In this guide, we’ll dive deep into everything you need to know about the Simmons 4 Inch Well Seal—from its components and maintenance routines to troubleshooting common problems. Whether you’re new to well ownership or looking for ways to enhance your existing setup, we’ve got you covered! Let’s get started on understanding how this incredible piece of equipment works for you.

Components of the Well Seal and their Functions

The Simmons 4 Inch Well Seal comprises several key components, each designed for specific functions.

At the top is the well cap. This sturdy piece protects the interior from contaminants while providing access for maintenance activities.

Beneath it lies a gasket, which creates an airtight seal. It prevents surface water and debris from entering the well, ensuring clean water supply.

Next is the riser pipe connection that links to your well casing. This component allows secure attachment and helps maintain structural integrity during use.

The vent is another critical part of this system. It balances air pressure within the well, preventing vacuum formation that could disrupt water flow.

Check valves may be included in some designs to prevent backflow into your well system. Each part plays a vital role in keeping your water source safe and efficient for years to come.

Importance of Proper Maintenance

Proper maintenance of the Simmons 4 Inch Well Seal is crucial for several reasons. It helps ensure that your water supply remains clean and free from contamination. A well-maintained seal prevents harmful substances from entering your well.

Regular upkeep also extends the lifespan of the well seal itself. Neglecting it can lead to wear and tear, resulting in costly repairs or replacements down the line.

Moreover, a properly functioning well seal contributes to overall system efficiency. This means you’ll enjoy better water pressure and flow rates without unnecessary strain on your pump.

Maintaining this component also supports environmental health by safeguarding groundwater resources. By keeping contaminants out, you’re protecting not only your own water supply but also local ecosystems impacted by potential leaks.

Investing time in maintenance pays off significantly—both economically and environmentally.

Step-by-Step Guide for Cleaning and Inspecting the Well Seal

Start by gathering your tools: a bucket, soft cloths, and a non-corrosive cleaner. Ensure you have gloves to protect your hands as well.

Begin the cleaning process by turning off the power supply to your pump. This ensures safety while working on the well seal.

Next, remove any debris or dirt around the seal’s surface using a dry cloth. Pay attention to crevices where grime can accumulate.

Once cleared, apply the non-corrosive cleaner with a damp cloth. Wipe gently but thoroughly to avoid damaging components.

After cleaning, inspect for cracks or signs of wear. Look closely at rubber gaskets and seals; these parts are crucial for maintaining water quality.

Check that everything is securely fastened before reactivating your system. Regular inspections help prevent bigger issues down the line.

Troubleshooting Common Issues with the Simmons 4 Inch Well Seal

When dealing with the Simmons 4 Inch Well Seal, some issues may arise that require your attention. One common problem is water leakage around the seal itself. This can often be traced back to improper installation or wear and tear over time.

Another issue might be difficulty in accessing the maintenance port. If debris accumulates, it could obstruct your ability to check on vital components. Regular cleaning of this area can prevent such blockages.

You may also notice a drop in water pressure from your well system. This could indicate a clog or malfunction within the seal assembly, requiring immediate inspection.

If you detect unusual noises during operation, it’s essential to investigate further. These sounds may signal underlying problems that need prompt resolution to ensure optimal performance of your well system.

When to Replace Your Well Seal

Recognizing when to replace your Simmons 4 Inch Well Seal is crucial for maintaining water quality and system efficiency. If you notice a drop in water pressure or strange odors, it may indicate seal deterioration.

Inspect the seal regularly for visible cracks or wear. Even minor damage can lead to significant issues over time.

If you’ve performed multiple cleanings without improvement, it’s likely time for a replacement. A well-maintained seal should function effectively with routine care.

Another sign is frequent contamination of your water supply. If contaminants seep through, the integrity of the seal has been compromised.

Also, consider age; seals have a lifespan influenced by environmental factors and materials used. When in doubt, consult with a professional to assess its condition accurately.

Tips for Choosing a Quality Replacement Well Seal

When selecting a replacement for your well seal, consider the material. Look for durable options like rubber or thermoplastic that can withstand environmental stresses.

Check compatibility with your existing system. A mismatch can lead to leaks and costly repairs down the line.

Don’t overlook the size. Ensure you choose a seal specifically designed for 4-inch wells to achieve an effective fit.

Review manufacturer reputation. Opting for trusted brands ensures better quality and reliable performance over time.

Inspect warranties offered by manufacturers as they often indicate confidence in their product’s durability.

Consult online reviews from other users. Their feedback can provide insights into real-world performance that specifications alone might not reveal.

Conclusion

Maintaining your Simmons 4 Inch Well Seal is crucial for ensuring the longevity and efficiency of your well system. A well-maintained seal protects against contamination, ensures optimal water flow, and prolongs the life of your equipment. By understanding its components and functions, you can spot potential issues early on.

Regular cleaning and inspection are key to preventing problems down the line. Following a step-by-step maintenance routine will not only keep your well running smoothly but also save you money on repairs or replacements.

If you encounter any common issues, knowing how to troubleshoot effectively can make all the difference in avoiding costly downtime. However, if a seal shows signs of extensive wear or damage, it may be time for a replacement.

Choosing a quality replacement with durability in mind will ensure that you continue to get reliable performance from your well for years to come. With proper care and attention, your Simmons 4 Inch Well Seal can serve as an invaluable part of your water system’s infrastructure.

Ethan Cole is a versatile writer at hsnime.co.uk, offering fresh perspectives and engaging content across various topics. With a passion for creativity and knowledge, Ethan aims to provide insightful articles that resonate with a diverse audience.